Product Search

Product Categories

Malleable Wire Rope Clips

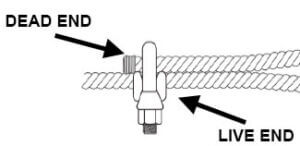

Never Saddle a Dead Horse

When using wire rope clips, (also know as wire rope clamps) always apply the saddle of clip to the “live side” or load bearing side of the cable assembly.

Methods Of Application

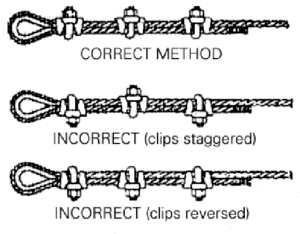

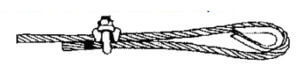

1. Always apply the saddle of the wire rope clip to the live end (non turnback end) of the wire rope or cable. “Never Saddle a Dead Horse.” Turn back the specified amount of rope from the thimble. Apply the first clip one base width from the dead end of the wire rope.

2. Apply the next clip as near the loop as possible. Turn on the nuts but do not tighten.

3. Space additional clips equally between the first two. Take up rope slack. Tighten all nuts evenly on all clips.

![]()

| STOCK NUMBER | SIZE | WEIGHT/100 PCS. | MINIMUM CLIPS REQUIRED | TORQUE IN LBS. FT.* | TURN BACK LENGTH | BULK PACKAGING |

|---|---|---|---|---|---|---|

| MWRC062 | 1/16″ | 3 lbs. | 3 | 2 | 3″ | 1000 pcs |

| MWRC125 | 1/8″ | 4 lbs. | 3 | 3 | 4 3/4″ | 1000 pcs |

| MWRC187 | 3/16″ | 7 lbs. | 3 | 4.5 | 5 1/2″ | 500 pcs |

| MWRC250 | 1/4″ | 14 lbs. | 3 | 15 | 7″ | 250 pcs |

| MWRC312 | 5/16″ | 15 lbs. | 3 | 15 | 7 3/4″ | 250 pcs |

| MWRC375 | 3/8″ | 21 lbs. | 3 | 30 | 9 1/2″ | 150 pcs |

| MWRC437 | 7/16″ | 37 lbs. | 4 | 40 | 10 1/4″ | 100 pcs |

| MWRC500 | 1/2″ | 38 lbs. | 4 | 45 | 15 1/4″ | 100 pcs |

| MWRC562 | 9/16″ | 59 lbs. | 4 | 50 | 16″ | 50 pcs |

| MWRC625 | 5/8″ | 59 lbs. | 4 | 75 | 16″ | 50 pcs |

| MWRC750 | 3/4″ | 84 lbs. | 5 | 75 | 22 1/4″ | 25 pcs |

| MWRC875 | 7/8″ | 125 lbs. | 5 | 130 | 23 1/2″ | 25 pcs |

| MWRC100 | 1″ | 166 lbs. | 6 | 130 | 31″ | 20 pcs |

| MWRC1125 | 1 1/8″ | 211 lbs. | 7 | 200 | 39 1/2″ | 10 pcs |

*Torque values shown are based on clean, unlubricated threads. Wire rope clips are not designed for load carrying purposes, therefore working load limits have not been established. To properly install a wire rope clip, a torque wrench must be used.

Note: Malleable Wire Rope Clips made according to Federal Specification FF-C-450 D, Type 1, Class 2. Forged Wire Rope Clips made according to Federal Specification FF-C-450 D, Type 1, Class 1.