Product Search

Product Categories

X100® Grade 100 Master Links W/ Sub Assembly

DESIGNED & SUITABLE FOR OVERHEAD LIFTING

- Designed & Suitable for Overhead Lifting

- Forged Alloy Steel

- Quenched & Tempered

- Powder Coated X100 BLAZE ORANGE

- 100% Proof Tested At 2X the Working Load Limit

- 100% Mag-Particle Crack Detection

- For Use In Fabricating 3 & 4-Leg Chain Slings

- With Flat Spots

| STOCK NUMBER | SIZE (IN) | CHAIN SIZE (IN) | WORKING LOAD LIMIT (LBS) | WEIGHT/PIECE (LBS) | |

|---|---|---|---|---|---|

| 5:1 WIRE ROPE OR SYNTHETIC | 4:1 CHAIN | ||||

| XMLSA19 | 3/4 | 9/32 | 8,960 | 11,200 | 3.0 |

| XMLSA22 | 7/8 | 5/16 | 12,160 | 15,200 | 4.5 |

| XMLSA26 | 1 | 3/8 | 20,800 | 26,000 | 7.8 |

| XMLSA32 | 1-1/4 | 1/2 | 31,200 | 39,000 | 13.3 |

| XMLSA38 | 1-1/2 | 5/8 | 48,880 | 61,000 | 25.3 |

WARNING: 5:1 working load limit ratio is for wire rope and synthetic slings. 4:1 working load limit ratio is for chain slings. Use caution when determining and selecting which master link is needed.

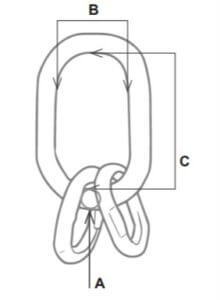

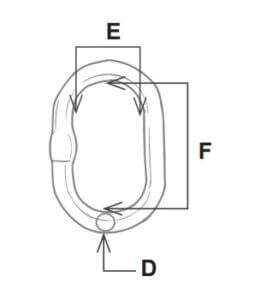

| STOCK NUMBER | DIMENSIONS (IN) | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| XMLSA19 | .75 | 2.77 | 5.51 | .51 | 1.54 | 3.26 |

| XMLSA22 | .91 | 3.54 | 6.30 | .65 | 1.54 | 3.26 |

| XMLSA26 | 1.06 | 3.62 | 7.21 | .75 | 2.15 | 4.00 |

| XMLSA32 | 1.30 | 4.33 | 8.78 | .91 | 2.26 | 4.00 |

| XMLSA38 | 1.50 | 5.51 | 10.70 | 1.06 | 4.06 | 7.20 |

First drawing (A-C) indicates master link. Second drawing (D-F) indicated sublinks.