Product Search

Product Categories

X100® Grade 100 Master Links

DESIGNED & SUITABLE FOR OVERHEAD LIFTING

- Designed & Suitable for Overhead Lifting

- Forged Alloy Steel

- Quenched & Tempered

- Powder Coated X100 BLAZE ORANGE

- 100% Proof Tested at 2X the Working Load Limit

- 100% Mag-Particle Crack Detection

- With Flat Spot

| STOCK NUMBER | SIZE (IN) | WORKING LOAD LIMIT (LBS) | WEIGHT/PIECE (LBS) | |

|---|---|---|---|---|

| 5:1 WIRE ROPE OR SYNTHETIC | 4:1 CHAIN | |||

| XML13 | 1/2 | 4,800 | 6,000 | 0.8 |

| XML16 | 5/8 | 6,880 | 8,600 | 1.5 |

| XML19 | 3/4 | 10,320 | 12,900 | 2.4 |

| XML22 | 7/8 | 14,080 | 17,600 | 3.3 |

| XML26 | 1 | 24,000 | 30,000 | 5.1 |

| XML32 | 1-1/4 | 36,100 | 45,200 | 8.8 |

| XML38 | 1-1/2 | 56,400 | 70,600 | 16.0 |

| XML45 | 1-3/4 | 84,700 | 105,900 | 27.5 |

| XML50 | 2 | 102,600 | 128,200 | 36.0 |

WARNING: 5:1 working load limit ratio is for wire rope and synthetic slings. 4:1 working load limit ratio is for chain slings. Use caution when determining and selecting which master link is needed.

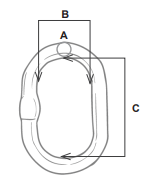

| STOCK NUMBER | DIMENSIONS (IN) | ||

|---|---|---|---|

| A | B | C | |

| XML13 | 0.51 | 2.37 | 4.35 |

| XML16 | 0.63 | 3.15 | 5.51 |

| XML19 | 0.75 | 3.54 | 6.30 |

| XML22 | 0.86 | 3.74 | 6.30 |

| XML26 | 1.02 | 3.93 | 7.09 |

| XML32 | 1.26 | 4.33 | 7.87 |

| XML38 | 1.50 | 5.91 | 10.83 |

| XML45 | 1.77 | 7.09 | 13.39 |

| XML50 | 1.97 | 7.48 | 13.78 |